Diesel generators have powered job sites for decades—but today’s construction environments demand more than brute force. While diesel systems are familiar and easy to deploy, they come with growing limitations that eat into your bottom line.

Excessive Fuel Consumption

Diesel generators often run at full capacity, even when the load doesn’t require it. This leads to wasted fuel—especially during idle periods or overnight when demand is low.

High Maintenance Demands

The more hours a generator runs, the more frequently it needs service. Oil changes, filter replacements, and wear-and-tear repairs add up fast. Frequent downtime means lost productivity and extra labor costs.

Noise and Pollution

Diesel engines are loud. On urban sites or near residential zones, this can lead to complaints, work restrictions, or even fines. On top of that, traditional generators emit high levels of CO₂ and particulate matter—making it harder to meet today’s environmental standards.

Regulatory Pressure

Construction companies are now under pressure to reduce emissions and improve sustainability. Many local, state, and federal contracts require compliance with Tier 4 Final emissions standards. Older diesel models fall short.

In short: traditional generators cost more to run, require more upkeep, and don’t align with where the industry is heading.

What Is a Hybrid Generator System?

A hybrid generator system is a smarter, more efficient way to power construction sites. It combines two energy sources—usually a diesel generator and a battery storage system—managed by a smart control unit that adjusts power output in real-time.

How It Works

Here’s what a hybrid setup looks like on-site:

- The battery system handles light loads during off-peak hours (overnight, breaks).

- When power demand increases, the generator turns on to support the load and recharge the battery.

- A smart controller automatically switches between power sources based on the actual energy draw from tools, trailers, and equipment.

The result is on-demand power delivery that adapts to how your team works—without wasting fuel or overworking your equipment.

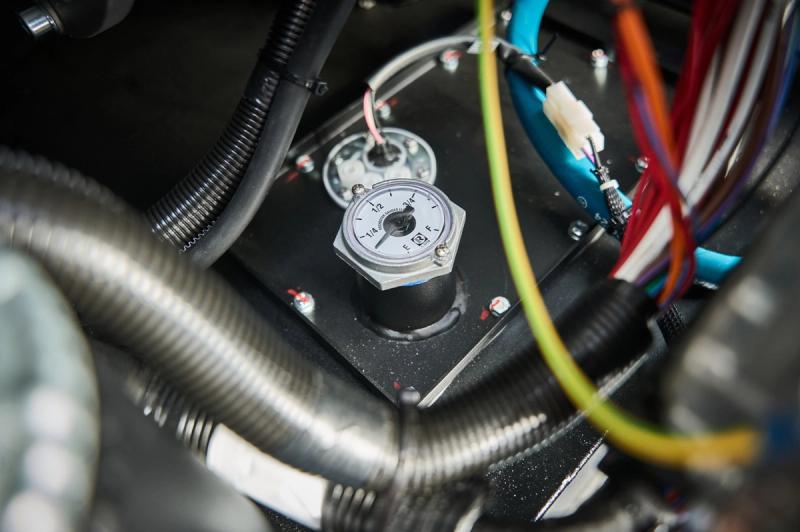

Core Components of a Hybrid Generator

| Component | Function |

|---|---|

| Generator (Diesel/Gas) | Provides backup and peak load power |

| Battery Storage System | Handles base load and stores excess energy |

| Smart Controller | Monitors demand, switches sources, and optimizes output |

| Optional Solar Input | In some systems, solar extends battery runtime |

Why it matters: This configuration reduces runtime, fuel use, emissions, and noise—making it a perfect fit for modern, efficiency-driven construction operations.

What Is a Hybrid Generator System?

A hybrid generator system is a modern power solution that combines a conventional fuel-powered generator with a battery energy storage system. It’s designed to deliver power based on actual site demand—not just run continuously like traditional diesel units.

This setup helps reduce fuel use, improve system efficiency, and extend equipment life—all without sacrificing performance.

Core Components

A well-designed hybrid generator includes:

- Generator (Diesel or Gas): Used to provide power during peak loads and recharge the battery bank when needed. Operates intermittently, not continuously.

- Battery Energy Storage System (BESS): Stores electricity and handles low-load demand during idle periods (overnight, breaks, or tool downtime). Reduces reliance on the generator.

- Smart Power Controller: Manages the switch between generator and battery in real-time. Tracks load, automates power flow, and prevents overuse of any single component.

This combination allows hybrid systems to match the power profile of a jobsite more efficiently than a standalone generator.

How It Works on the Jobsite

Here’s how a hybrid power system typically operates:

- Battery-first operation: The system uses battery power during low-load hours—keeping the generator off.

- Demand-triggered generation: When power needs rise, the generator activates automatically to supply energy and recharge the batteries.

- Smart control: A central unit constantly monitors site demand and adjusts the power source as needed. This reduces fuel burn, avoids generator overuse, and ensures reliable performance across shifting load conditions.

Hybrid generators provide responsive, demand-based power delivery, unlike fixed-RPM diesel systems that run continuously regardless of load.

Reasons Hybrid Generators Work Better for Construction

Contractors are switching to hybrid systems not because they’re trendy—but because they solve real jobsite problems. Here’s why hybrid outperforms diesel in the field.

Fuel Savings

Hybrid generators are engineered to run only when needed. During light-load conditions, the battery takes over. This can result in:

- Up to 90% fuel savings on jobs with intermittent power needs

- Fewer fuel deliveries, which reduces downtime and logistical costs

By cutting idle engine hours, hybrid systems keep daily fuel consumption low—even on long shifts.

Maintenance Reduction

Every hour a diesel engine runs adds wear and requires service. Hybrid systems lower engine runtime significantly, which means:

- Fewer oil changes, filters, and repairs

- Longer intervals between scheduled service

- Reduced labor and maintenance overhead

This is especially valuable for remote jobs where service teams are expensive to dispatch.

Quieter Operation

Battery-powered operation is nearly silent. On jobsites where sound matters, this makes a real difference.

- Eliminates generator noise during low-demand hours

- Ideal for urban, school-adjacent, or residential projects

- Helps crews comply with local ordinances and work longer hours where noise limits apply

Lower Emissions

Many construction sites now face strict environmental rules. Hybrid systems help meet them by:

- Operating under Tier 4 Final emissions standards

- Reducing generator run time and fuel combustion

- Supporting compliance with ESG requirements on public and private contracts

Hybrid solutions align with sustainability goals without sacrificing power.

Flexibility & Deployment

Hybrid systems are modular, compact, and easy to deploy. They’re ideal for:

- Remote or temporary sites with no grid access

- Pop-up projects, including telecom, bridge repair, or road crews

- Contractors who need portable systems that scale across multiple projects

With fewer components and more automation, hybrid generators are often faster to install and easier to manage than conventional power setups.

Hybrid vs. Diesel: Performance and ROI Compared

If you're still running diesel-only generators on every job, you're likely spending more than you need to—and getting less in return. Here's how hybrid vs. diesel generators compare in the real world:

Side-by-Side Comparison Table

| Feature | Diesel Generator | Hybrid Generator |

|---|---|---|

| Fuel Use | Always high (runs continuously) | Demand-based (runs only when needed) |

| Maintenance Frequency | Frequent (oil changes, filters, servicing) | Reduced (less engine runtime) |

| Noise Output | Loud and constant | Quiet during battery operation |

| Emissions | High CO₂ output, Tier 2 or below | Low emissions, Tier 4 compliant |

| Typical ROI Timeline | 3–5 years | 8–16 months, depending on load and usage |

This table isn’t theoretical—it reflects what contractors are reporting in the field. In real jobsite conditions, hybrid generators cut costs across fuel, maintenance, and logistics.

Why Hybrid Pays Off Faster Than You Think

It’s not just about cleaner power—it’s about better business math. Here's why hybrid generator ROI makes sense for construction firms:

- Lower Lifetime Operating Cost You burn less fuel and put fewer hours on your generator, which means it lasts longer and costs less to own over time.

- Reduced Service Overhead Fewer oil changes, less downtime, and reduced labor for repairs. That translates directly into savings and less jobsite disruption.

- Fewer Penalties or Delays Meeting emissions and noise standards reduces the risk of fines, shutdowns, or complaints—especially in city projects or government-funded work.

Contractors who switch typically recoup their investment in 12 months or less, especially on multi-phase or year-round projects.

Who Should Switch to Hybrid Generators?

Hybrid generators are not just for “green” projects. They’re built for crews who need efficient, flexible, and dependable power—on any size jobsite.

Ideal Users Include

- General Contractors Managing multiple projects and looking to cut operating costs across the board.

- Urban Construction Firms Working in noise- or emission-restricted zones that require silent or low-impact equipment.

- Remote Infrastructure Teams Building or servicing roads, bridges, telecom towers, or pipelines—where grid power isn’t available.

- Any Contractor Focused on Budget + Compliance Companies bidding on public or commercial projects with strict ESG, Tier 4, or noise standards.

If your team is balancing tight margins, growing regulations, and unpredictable power needs—a hybrid system is a strategic advantage.

Final Thoughts: Is It Time to Upgrade Your Jobsite Power?

The construction industry is evolving—and so is the way contractors power their jobsites.

Traditional diesel generators are no longer the most efficient or compliant choice. With rising fuel prices, tougher regulations, and increased demand for sustainable operations, hybrid generators offer a smarter, future-ready alternative.

Let’s Recap the Key Benefits:

- Fuel savings up to 90% in low-load conditions

- Lower maintenance costs thanks to reduced engine runtime

- Quieter operation ideal for urban and residential sites

- Tier 4 Final compliance to meet strict emissions regulations

- Portable and scalable systems for remote and multi-phase projects

Hybrid power doesn’t just reduce costs—it creates more flexibility, improves project timelines, and positions your business for long-term success.

If you’re ready to reduce operating costs and stay ahead of compliance requirements, now is the time to make the switch.

Contact Select Energy Today

Talk to our team about how a hybrid power system can fit into your next project.From equipment specs to ROI planning, we’ll help you take control of your jobsite power—cleaner, quieter, and more efficient than ever.